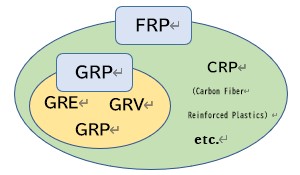

What is FRP

FRP stands for Fiber Reinforced Plastic and are classified depending on the fiber material and type of resin used. For glass fiber material, it is classified as follows

Epoxy resin → GRE (Glass Fiber Reinforced Epoxy)

Vinylester resin → GRV (Glass Fiber Reinforced Vinylester)

Polyester resin → GRP (Glass Fiber Reinforced Polyester)

Since the chemical resistance, strength, and cost vary depending on the resin used, it is necessary to select the optimum material according to the required specifications.

Features of FRP Piping

[Durability and corrosion resistance] |

[Lightweight → Easy to install] |

|---|---|

| It is inert to internal corrosion of pipes caused by water, seawater, industrial wastewater, chemicals, residues and bacteria. Similarly, it resists exterior corrosion even in aggressive environments, thus cathodic protection is not required. Also, because flame-retardant materials are used, it is not limited to places where flame-retardant is required. |

Since it has a lower specific density of about 1/4 ~ 1/8 equivalent to steel pipes, it can be installed up to a certain size without using a heavy equipment and it is easy to handle during installation. |

[Low thermal conductivity] |

[Wide range of piping system] |

| FRP piping material are good heat insulators due to its low thermal conductivity of approximately 1%. This makes the FRP piping suppress significant amount of heat loss compared to steel under the same conditions. | A complete line of standard sizes is available up to of 1,000 mm (40 in.) diameter, 12 m (40 ft.) length, and 75 bar (7.5 MPa) pressure resistance.

Large diameter piping of up to 3,000 mm (120 in.) can be custom-made or manufactured for GRV/GRP |

【LongER life】 |

[NO CONTAMINATION] |

| FRP piping’s durability promotes longer life expectancy in service compared to other materials. | FRP piping is resistant to scale and rust which allow contamination and causes failure of steam traps, valves and other components. |

[COST EFFECTIVE] |

[Various fittings] |

| Due to FRP piping longevity, it reduces or eliminates the cost of replacement. Also, FRP piping does not require the application of rust-preventive coating for the inner lining which is basically required for steel pipe construction and regular re-rust preventive coating work for maintenance or repair work.

In addition, FRP piping inner surface has a relatively low coefficient of friction which minimizes pressure drop resulting in lower energy consumption and operating cost. Moreover, low coefficient of friction prevents adhesion of marine organisms which makes it basically maintenance-free for 25 years. |

We also provide a wide variety of fittings and flanges that comply with each major international standard, so they can be connected to all kinds of pipes.

• Elbow • Tee • Reducer (concentric, eccentric) |

WIDE RANGE OF APPLICATION (Major Applications)

| Cooling Water | Seawater Supply | Chemical Processing |

| Firewater / Fire Protection | Steam Condensate Return | Wastewater |

| Industrial Water | Potable Water | Process Water |

| District Heating | Sprinkler Water | General Water Service |

etc

Wide Range of System

GRP / GRV Piping

| Size | 1-120inch (25-3000A) |

| Pressure Classification | Max. 16 bar(1.6 MPa) Or higher, please consult us separately |

| Internal Lining Thickness | 0.5 mm (varies depending on specification) |

GRE Piping

| size | 1-40 inch (25-1000A) |

| Pressure Classification | Max. 75 bar (7.5 MPa) |

| Internal Lining Thickness | 0.5mm |

GRP (Polyester) Piping / GRV (Vinylester) Piping

We can provide large diameter of up to 3,000 mm (120 in.) which is commonly used for intake piping. This can also be used for outdoor piping.

In addition, it can be prefabricated into complex and special shapes (e.g. manifold piping) as per customer’s request and design requirement.

We select and provide the optimum resin material, inner layer thickness, and weatherproof layer (outermost layer) thickness according to the usage environment, fluid, pressure, and diameter.

Sample Photo of GRP/GRV Large Diameter Piping

GRE (Epoxy) Piping / BONDSTRAND SERIES

GRE piping, which has extremely excellent corrosion resistance, is used in a wide variety of applications from water supply to fuel processing.

We also design and provide special piping systems for fire protection and food processing processes.

FAQ

In addition, as shown below, we have production bases outsourced from different countries, and we propose the optimum supply chain considering specifications and delivery destinations.

* Vendors’ Manufacturing Countries: Malaysia, Indonesia, South Korea, Thailand, Japan, etc.

-FRP has higher pressure resistance than PVC.

-It is chemically non-reactive, thus compatible for chemical lines application.

-More superior in corrosion resistance and electrolytic corrosion resistance.

-FRP is more suitable to use in seawater lines than stainless steel due to its excellent corrosion resistance.

– FRP has excellent chemical resistance than stainless steel.

-We offer butt & wrap joint and adhesive-bonded joint (Bondstrand® Series) type which is used generally. In case of adhesive-bonded joint, installation time can be significantly shortened compared to butt & wrap joint.

OKAMURA

1-10-1, Shichinomiya-cho, Hyogo-ku,

Kobe, Japan 652-0831

TEL: +81-78- 652-3151